General Ideas

An estimate was requested by Tom Hepburn for a dock from Viking Wood Products. A quote was received via email.

The quote was PDF’d and is available by clicking this link:

A price sheet with options was also obtained from PipeFusion. They supplied the floatation devices for the new docks at Canoe Lake. See http://pipefusion.com/floating-docks-pontoons.html for more information.

Dave is concerned that the Pipefusion option will make the dock too high to open the boathouse doors. Also because the pipeFusion docks sit higher above the water, they are not as stable as the foam billet docks we are more used to. This may not be a problem now but as we all get older (and or drunker) it may become an issue in the future to consider.

Any new dock will require money to replace. We need to establish a budget that everyone can contribute equally to. Please log in and contribute to the discussion.

James offered up some of the fir left-over from his house build for the dock. The price is right, but there is some concern regarding the splintering tendency of fir. Perhaps it could be used for the framing but use an alternate product for the deck? James and Tom could prefab the dock here, then haul it out and put it together on-site. —Lhepburn (talk) 08:10, 15 October 2013 (MDT)

Tom mentioned that James says he may be able to arrange transport for the lumber if we pre-fab the dock. If we knew the details it would help us decide on who/when/how the dock will be built. Things to consider:

- What would be the cost for gas etc to transport lumber if James can’t arrange alternate transport?

- Do we have access to a vehicle that will handle hauling the lumber out? (James do you have anything appropriate?)

- If James can arrange alternate transport, where will it deliver and will further transport to the park still be required?

- Would alternate transport be scheduled or spur of the moment? This will have implications for meeting the delivery on the other end.

- Who is available to assemble dock before ice goes out, and what is the cost of travel to get there? (Tom can possibly commit the time, will look into the cost of a flight and car rental)

- What is the cost for locally sourced decking material?

- Can the decking be installed in the summer or does it need to be done when the framing is done? Would arrangements need to be made to have decking material delivered when the framing is being assembled?

- If set-up person is flying in, are there appropriate tools at the cottage to do the job or would extra baggage be required?

- What is the cost of buying the equivalent lumber in Ontario, and can it be delivered to the lake?

- How will building materials be transported across the ice?

Functions of the dock

It has been suggested that the dock have the ability to function as a barge as well. Tom Pigeon has a barge that normally is parked and the motor removed. It functions as a dock most of the time. Tom’s barge/dock has the motor on it all summer but I am not suggesting we do that. I do think that building a dock that can do double duty as a barge is a prudent way to maximize the value of our dollars. James here and I have some thoughts that are up for debate: Yes I have plenty of 2 x 10 x 20′ fir that would make an awesome dock or2. I used it to make a east facing deck. The square beams under the boathouse are 20′ fir 8×8 and are good for wet applications I have given the project some thought and it could be done with minimal fuss. Between all of us we have all the tools, material , knowledge,I could round up transportation with truck and trailer ( was thinking our making dock part of trailers other would be no trailer on return trip to bring back) Such a project is kind of fun for me but I am starting to find out that not many other people see it that way :(. We might want some good drawings and markings on boards so it goes together like ikea furniture. Costs would be stainless hardware ,floatation( bought in ont.) , rum to keep me patient and listening to other people more organized than me . Maybe some extra drill batteries and chargers as it would be pre drilled and screwed together on site. Of course family members precious spare time because I would like some other input. I would like to thank Ian for keeping the old docks going for as long as they have. I would absolutely have the dock double as a barge and have the floats designed as such. Maybe with a bolt on transom On our deck we stained it clear which may have reduced splinters but regardless I think it is a non issue , wet wood has less slivers add picture here Done – Sysop Example of Fir Decking with clear stain that James is referring to.

Financial Considerations

There have been references to costs in other areas of the page, so I think it is time we made a new category heading for the subject —Tom Hepburn (talk) 22:07, 8 April 2014 (MDT) Regarding costs of fir dock. – screws and hardware stainless or brass I will look into costs and give a ‘rule-of-thumb’ for quanities —Tom Hepburn (talk) 19:13, 10 April 2014 (MDT) – fuel to drive out during holiday in pickup with trailer and back maybe without trailer because dock would be the trailer , could load axle in back of truck for return trip What does the vehicle get for gas mileage? – screw driver bits and drill bits , power charging drills, 10″ saw blade I believe that a good’ol brace and bit will almost keep pace with running dead batteries across the lake. Does anyone know someone that would loan a compact generator. Phill Cousine has a very small one that I’ve been quite impressed with. It’s Honda, small as a carry-on suit-case, and uses tiny amounts of fuel. I’m not sure he would loan it to anyone. James was thinking of doing all the screw holes and predrilling in the prefab stage before loading – of course – time- How long does it take to plan out a deck .? And build it. 3 weekends, couple guys? When? I think that winter would be the best time since you have a flat surface for assembly (the lake). It would go faster on a frozen lake. I’ve checked with MNR and they are okay with that. —Tom Hepburn (talk) 19:13, 10 April 2014 (MDT) – lumber is all here at JDH place and room to do it all I need is help and beer – floatation in Ont.

20 May 2014 Cost Update

We currently have no fixed cost for the project material other than the lumber, which is, according to JDH, free. If a truck is used, we could calculate an average 14 L/100Km x 3200Km = 448 L fuel. Assume $1.38/L gas x 448 L = $618 for gas. lumber is not free.

Price Quote from Huntsville for Floatation 21 May 2014

on 21 May 2014 User talk:Heather obtained a price quote for floatation material. She phone it into me – User talk:Tom Hepburn a couple days later Here’s what she said:

- Quote is from Rolston’s Home Hardware in Huntsville

- Blue foam billets are dimensioned 96″x20″x7″

- $114.97/each

- For 10 billets, all tax inclusive, delivery on any given Friday, total cost $1299.60

- Permafloat system billets are available too

- for regularly stocked item, dimensions are 2’x4’x12″

- $129.00 each

- Total cost with tax and delivery, $1468.98

- Author’s Note: Permafloat sells direct off their website so you can see other sizes and prices (not sure if Canadian or not) Here is the link: http://www.permafloats.com/

Estimate From Red Deer Fasteners

Here is the price quote from Red Deer Fasteners. File:Estimate from Red Deer Fasteners for SS dock screws.pdf It took quite a while for me to get it this far. Sorry. —Tom Hepburn (talk) 17:28, 13 November 2014 (MST)

I have looked on eBay.ca and looks like we can get very good prices on stainless steel deck screws10x3 might be worth it.User:James hepburn James; you should get a price and document the web address where you find the screws so we can compare and make a decision. —Tom Hepburn (talk) 21:29, 21 April 2015 (MDT)

My final thought on this project is this: It is taking away funds for, what I believe to be, a much bigger problem. The main building has serious structural integrity problems. Everyone seems to be ignoring the issue of the cottage leaning at 17 degrees and focusing on something that we could do without for a year – the dock. However, we would sorely miss the main building if it fell apart. —Tom Hepburn (talk) 23:14, 20 May 2014 (MDT)

jamoes James has a truck supplied by Don Fieber for the dock transportation and the material should go on the roof as for floats it doesn’t matter to me which ones as long as we have dimensions of floats before marking out lumber

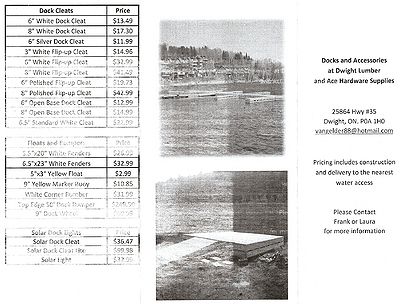

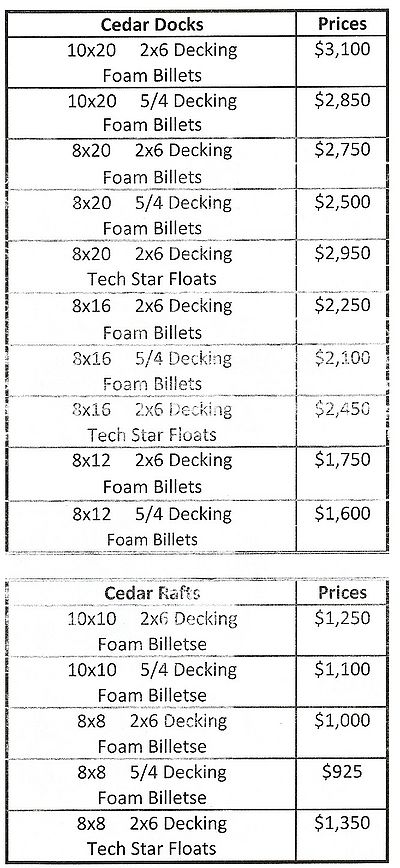

Price Sheets and Estimates April 2015

Dave got some price sheets and estimates from several places

Dwight Lumber Pre-fab dock prices

Note that we would have to buy a cedar dock, since the park is “moving away from” pressure treated lumber (meaning it wouldn’t be approved).

There is also a 2 page pdf here: File:dwight lumber prefab dock prices.pdf

Rolston Home Hardware Estimate for Permafloat Billets

Note that this quote is for a size that is “in stock” and not the size we need. It’s a best guess.

PDF file is here: File:Rolston home building centre quote for floatations March26-2015.pdf

New Dock Plan with Permafloat systems Sept 28 2014

An Update on the dock plan. We have made slight changes to the dimensions of the dock. It will remain 16′ x 20′ overall but will include a skirt board on the narrow sides. This allows for a reduction in the length of the longest frame members.

The following is the cut list:

| lenght ft | Length Inches | Quantity Needed |

|---|---|---|

| 19.75 | 237 | 7 |

| 16 | 192 | 30 |

| 6 | 74 | 4 |

| 4 | 48 | 4 |

| 3 | 36.25 | 16 |

Correction to the Cut List Table

There was an error in my calculation of the weight. I’ve placed here an updated table to show the weight calculation.

| Item | lenght ft | Length Inches | Quantity Needed | wieght in lbs | ||||

|---|---|---|---|---|---|---|---|---|

| weight | ||||||||

| frame | 19.75 | 237 | 7 | 603.3 | 0.3636 | lbs/inch | ||

| frame | 16 | 192 | 6 | 418.9 | ||||

| decking | 16 | 192 | 24 | 1675.6 | ||||

| frame | 6 | 74 | 4 | 107.6 | ||||

| frame | 4 | 48 | 4 | 69.8 | ||||

| frame | 3 | 36.25 | 16 | 210.9 | ||||

| Totals | 64.94 | 779.25 | 61 | 3086.2 |

I, User:Dave, think it may be a good idea to add a second float in the middle of each flotation section. That way we have even flotation front to back and side to side hopefully reducing any additional flexing torsion. Also, it will make sure that we have enough flotation for the weight of wood. –([User:Dave|Dave]…User talk:Dave

Info on the cottage bank account idea is on it's own page here: Cottage Bank Account

So it sounds like there’s general agreement on a pre-built dock to haul out. Should we vote to confirm? Then the question is, when to build it? Tom and I are going away shortly, and when we get back, May is already almost completely booked, and June will be busy too. If the dock is going out this summer, we need to schedule in some work time to get the pre-fab done. Here are some week-ends Tom and I have free at this time: May 24-25, June 7-8, June 21-22. Not sure how long until James’ shoulder will allow him to swing a hammer, but I’m sure he can perform a Foreman role if it’s not ready. We should be able to round up enough bodies for the grunt work. James – perhaps while you’re laid up you could work on the plans? —Lhepburn (talk) 07:56, 14 April 2014 (MDT)

May 2014 Update by TGH

There have been some phone conversations and person-to-person conversations between my self and others.

Talk with JDH

I will point form the talk. later I may return to fill in some grey areas. I’m currently short of spare time.

- James and I talked about prefabrication of a dock here in Alberta

- discussed some technical aspects such as final resting height vs wood submerged in the water.

- There is a difference of a couple inches between the 2×10 lumber and the 7inch billets of “styrofoam” that is commonly used; a solution is needed

- JDH has a truck, which requires minor tune-up before making a trip to ON.

- The truck would require a rack/rail system to hold all the lumber – 20foot lenghts – over the roof of the cab. This could be welded, bought on kijiji or elsewhere

- Stainless steel hardware seems the right choice, but for now the only cost talked about was $0.14/screw for the decking.

- JDH favors building on the beach and pushing into the water to complete top decking. I favor a winter build on the ice.

- IWH was contacted by JDH via texting and did not seem interested in joining this site, the work effort, or using the place much…yet. Hopefully that changes; contact JDH for more details.

Talk with Dave

Dave phoned at the end of May long weekend

- he suggested instead of flying out he could drive the truck if lumber and truck was ready.

- We discussed cost of driving and the currently unknown additional costs of the project: floatation billets and complete hardware.

- Dave thought in was within our reach to find time to pre-fabricate the dock and have the truck ready to go by beginning of July. I do not think it’s possible for me to commit the time necessary for this to happen since multiple cars have broken down recently. May 24 weekend is no longer available.

Dock Plan Based on Tom Peigons Dock

When Dave Returned from out east on August 20th, he emailed a hand drawn diagram of Tom Piegion’s dock/barge. I’ve converted it here with a link to the PDF. The plan is to make this into a parts diagram that we can make a Cut list for the material that JDH has supplied. See Below…

I have noticed that the billet sizes from HRH quote in Huntsville and the size listed in the drawing do not match. What should we do??? —Tom Hepburn (talk) 23:25, 25 August 2014 (MDT)

The PDF file can be accessed through this link: File:Dock Plan.pdf

CAD Drawing

Here is a mock-up of the corner detail

What thickness of steel should we use?? Should it be aluminum?? —Tom Hepburn (talk) 23:25, 25 August 2014 (MDT)

Here is the dimensions for the billet frame. Is it right to hold the foam as quoted??

I am not sure if the demensions font size is right, so here is the PDF

File:New Dock Corner Detail_skp.pdf

File:New Dock billets demensions.pdf

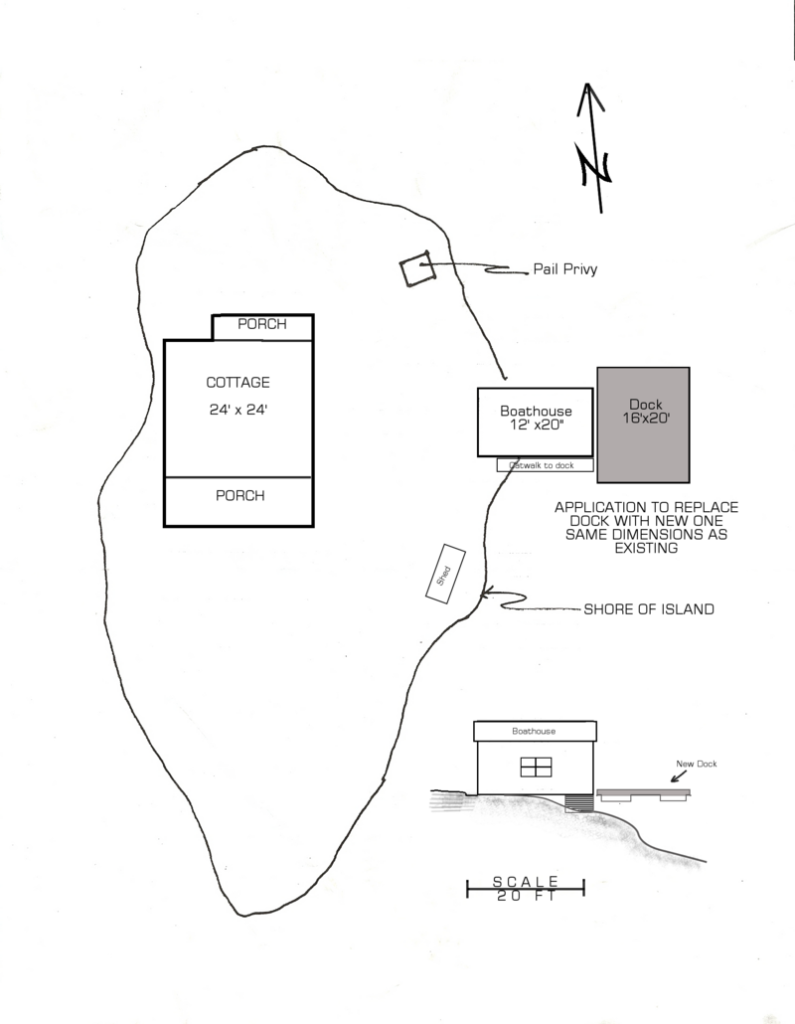

2015 Application for Permit to Construct a new Dock

I have made an application for the permit up but have not sent it off. Part of the permit application includes a scaled drawing of the lease showing all existing structures and the proposed work to be done.

here is the one I made basd off of R. L. Hepburns application to do work on the back porch. If there are any issues or concerns, you better speak up soon, as I am putting the application to gether and if will be sent electronically in the next couple of days. —Tom Hepburn (talk) 12:58, 8 April 2015 (MDT)

Enquiry with MNR July 2014

I sent an email out to the east gate and asked about projects that are carried out on the ice. I have not heard back from them yet. Tom Hepburn (talk) 14:01, 4 July 2014 (MDT)

Enquiry with MNR February 2015

I got in contact with MNR about dock permit and am currently make out the application with the required survey. I’ll update and upload some of the file when time permits. —Tom Hepburn (talk) 22:27, 12 March 2015 (MDT)

Email Submission of Permit Application and Survey Sketch April 2015

I have sent an application to the MNR on April 15, 2015. A pdf of the application is here and I will copy the txt of the email body here:

Ian Sernoskie;

Thanks for the information you gave to me. There have been some lengthy delays but I have managed to get all the information put together into a pdf document that I will attach to this email. It is still our hope to assemble the replacement dock in July of this year.

I will lay out our reasoning and action plan for assembling the dock sub-structure at the leaseholder landing area.

- A suitable building site for the dock does not exist on our lease. The existing dock would have afforded a level surface, however the dock is past the point of being able to support a single persons weight without submerging. Our island lease is approximately 2000 square feet of rock with no suitablely flat surface for building a dock frame. Our only option if we were required to assemble on our lease would require us to be walking in and disturbing the shorelines of Cache Lake. By building the frame at the leaseholder landing, a suitable area is available without disturbing shoreline lake bottom.

- The transportation of the materials would require many trips in a powerboat. As well, our application states that cordless power tools will be used and the charging of them will be done from an equipped vehicle which would involve further lake traffic. Our choice to use and charge cordless tools is motivated by the desire to eliminate power generator use, which results in more emissions and noise pollution than an idling vehicle. By building at the leaseholder landing, lake traffic, noise pollution and emissions derived from the project would be reduced significantly. The dock framed would be towed to it’s final position by powerboat. Â

- The length of time spent occupying the leaseholder landing will be minimized by assembling only to a point where the dock can be floated. Decking will be stacked and secured using hand tools at our lease. The dock material and components have been precut and are in “knock-down” format (think Ikea furniture) to reduce assembly time further.

Hopefully I’ve included everything you need in this application. If you need anything else, my contact information is below.

Thanks for all your help.

Thomas Hepburn

h)403-227-1759

c)403-588-3164Â <<<best option; you can txt too.

Attachment: Application_for_dock_replacement01.pdf

On 15-02-24 03:37 PM, Sernoskie, Ian (MNRF) wrote:

Dear Mr. Hepburn,

I am sorry for not being able to respond to your email and voicemail sooner.

I have left you a voicemail message on your home telephone, however I figured that I’d send you an email as well, just to be certain you received my reply.

Next to each of your questions in your previous email below I have written my responses.

In addition, I just wanted to make sure you had the proper documents for your work permit application (see attached). I realize you mentioned, in your earlier email, you possessed a copy of the “Application To Do Work On Shorelands (Part 3),” however, I figured I’d just send you a copy, in addition to the “Application for Work Permit – Part 1,” for your convenience.

It would be much appreciated, within your submission, that you provide a clear diagram/drawing with dimensions of both dock structures – that which is new and that which is to be replaced. As well, a map of your lease with a sketch of the dock in relationship to other structures will also be required. Pictures of the existing dock structure would also be appreciated, but are not absolutely necessary.

Please note, the surface area of your previous dock (footprint) will dictate the maximum surface area of your replacement dock. Additionally, we are also currently moving away from the use of pressure treated materials in dock construction, as well as striving for docks which impact the shorelands less – i.e. floating docks instead of crib docks. Finally, your new dock should be placed in the same area of your replacement dock. Please take this into consideration when developing your plans for submission.

Also note, we are currently evaluating dock repairs/replacements on a case-by-case basis. As a result of the spring 2013 freshet causing damage to numerous shoreland structures, we understand that there is a need for the rebuild/replacement of docks, and as such have made some specific allowances. That said, we also can’t always guarantee that a work permit or your original plans will necessarily be issued a work permit at this time, due to limitations currently imposed upon cottage leasehold construction and development in Algonquin Park.

Finally, I was simply wondering how imperative is it that you perform construction at the leaseholder landing? In addition, please include plans as to how you would move the replacement structure to your lease, as well as dispose of the existing one.

Feel free to contact me with any further questions or concerns. My contact details, and submission information, is provided at the end of this email.

Thank you.

Respectfully,

Ian Sernoskie A/Resource Management Technician Algonquin Provincial Park Telephone: (613) 637-2780 Ext. 352 Fax: (613) 637-2864 (Attn: Ian Sernoskie A/Resource Tech.) Email: <a class=”moz-txt-link-abbreviated” href=”mailto:ian.sernoskie@ontario.ca“>ian.sernoskie@ontario.ca</a> Address: Algonquin Park, East Gate Complex, Hwy 60 PO Box 219 Whitney, Ontario K0J 2M0

—–Original Message—– From: Hepburn [<a class=”moz-txt-link-freetext” href=”mailto:hepburn@hepburnhome.ca“>mailto:hepburn@hepburnhome.ca</a>] Sent: February 20, 2015 4:11 PM To: Sernoskie, Ian (MNRF) Cc: <a class=”moz-txt-link-abbreviated” href=”mailto:hepburn@xplornet.ca“>hepburn@xplornet.ca</a> Subject: Lease No. 1255

Hello Ian Sernoskie;

I left a message on your phone today and wanted to follow up with an email.

If my sources are correct, you are currently taking care of leaseholder permit requests. I had mentioned our need for a new dock a while ago and we still want to construct one this summer. Our latest plan is to construct it on the shores of the Rec-hall parking lot at Cache lake.

I have a copy of the Permit form “Application to Do Work on Shorelands” which I believe is the correct form to fill out. I only have a couple of questions:

1) Can I fill out this form and send it via email in PDF format? Yes. 2) Is there a fee that goes along with the permit? No.

Hopefully you can help me with this process. I look forward to hearing from you.

Thomas Hepburn h:403-227-1759 c:403-588-3164

Phone Call to MNR May 6, 2015

I made a phone call to MNR this morning and talked with Ian Sernoskie. He looked at the application while on the phone and said there seems to be no issues other than the requested start date.

There is a shoreline restriction for applications until July 15 of each year. The dock is not a shoreline crib dock, but he still asked if we could moved the construction, or at least the moving of the dock frame into the water until after the 15th of July.

—Tom Hepburn (talk) 09:38, 6 May 2015 (MDT)

We could build the underneath frames on the old dock or within the boat house then float them to the beach area to put on the top. Dave

See Also (links to other pages)

Well after the new dock completion, I am very pleased as to how the whole project turned out. Lots of people had a hand in the whole process and a lot of laughs along the way. It all turned out almost as I imagined. I am not sure we could have done it any better or any more cost effective. Way to go to go everyone involved! Impressive ! I want to build a transom on the dock for future use. Cottage maintainancewill always be an ongoing issue but hopefully somehow we can make it fun or at least not horrible. I will try to atattch some pics of finished dock with trim board

Retrieved from “http://cottage.hepburnhome.ca/index.php?title=New_Dock&oldid=1334“